Our erectors were first designed for the glass container industry, so you can rest assured our machines can assemble the packaging needed to protect even the most delicate bottles. Our erectors offer numerous options for your packaging needs. From the CE-20/30 and CE-24/30 for oversized and jumbo cases to the servo enhanced Mod B, we have a case erector for every budget and beverage.

Keeping individual containers from contacting one another is essential for making sure you don’t lose product on its way to the customer, and we’ve been the premier supplier of partitioner inserters to the beverage industry for over 35 years. Wayne Partition Inserters maintain full control of the partition, handling both sides simultaneously until it is seated. We offer numerous products; like the SF 400VHS and the SF-400 Quattro, capable of two or four insertions at once, the C-Pad partition inserter for pad inserting, or the SF-400 enhanced series for corrugated partition folding

Ensuring reliable, repeatable sealing is key to making sure your packages don’t open, and potentially spoil your product before it reaches shelves. Wayne Automation casetop sealers use repeatable servos for folding major and minor flaps, and can holt melt up to 80 cases per minute for rapid throughput

To get the most volume out of your packaging, you may want individual trays you can stack, and Wayne Automation offers the TR-50 trayformers to meet those needs. The TR-50 can make trays at up to 55 per minute, utilizing a mechanical pick and place system for precise handling at high speeds

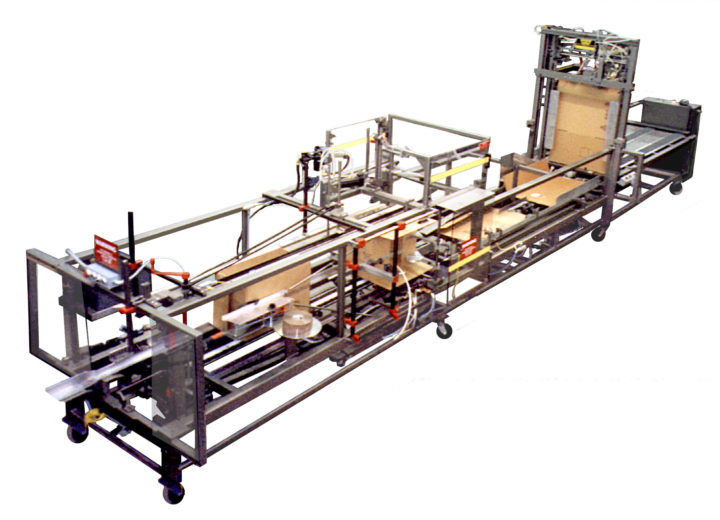

Once you’ve assembled your cases, inserted your partitions and built your trays, you’ll need to fill your trays, and our WTP Tray Packer was designed for the craft brewery industry to do just that.Our packers can be configured for cases of bottles, cans, cartons or ring cans, providing you the flexibility to package and safely transport soda, beer, tea, or anything else.