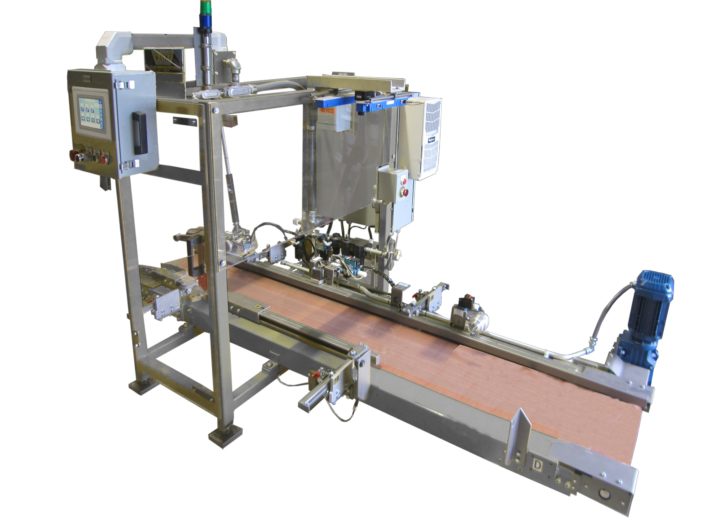

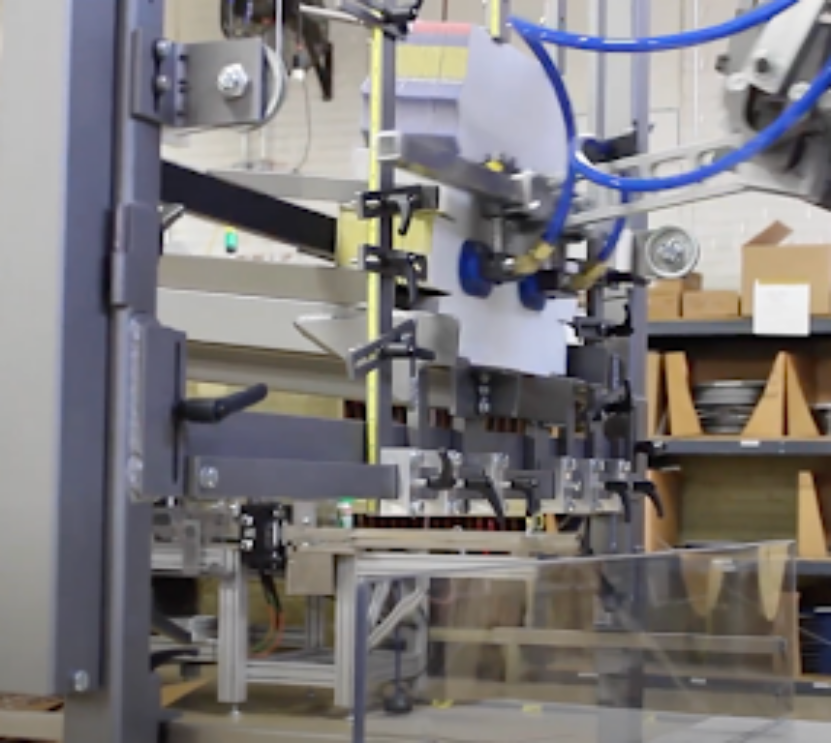

High-speed partition insertion is nothing without reliability and quality. The SF-400 Quattro follows the same ethos as all of our other partition handling machines; 100% control of the paper at all times. The SF-400 Quattro does not flip open partitions nor drop them into cases. Partitions are controlled by opposing sets of vacuum arms that open the partition to the proper position. The partition is placed into the waiting case via our servo inserter head and is only released when it has been inserted into the correct position in the case.

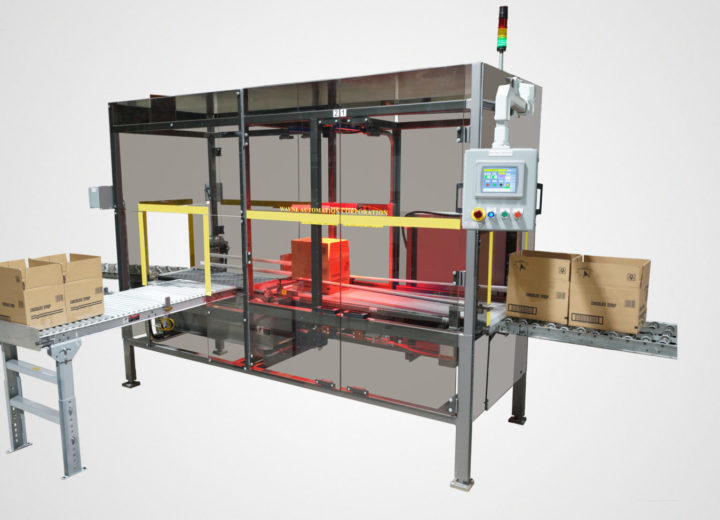

The servo-driven case exchange precisely places cases at the insertion station to ensure that lightweight, empty cases are exactly where they need to be to guarantee reliable insertions.

Wayne Automation Partition Inserters have a proven track record of performance that has made us the leader in partition handling.