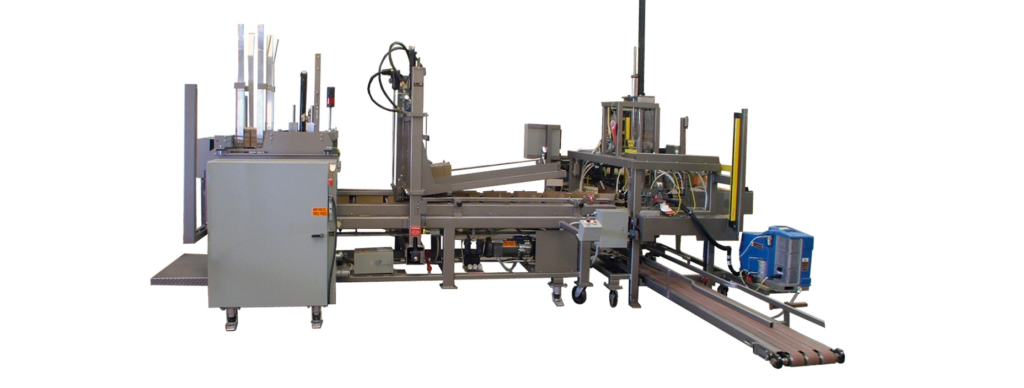

Regardless of your company’s needs, Wayne Automation partition inserters and packaging systems can deliver. Some of the most common applications are:

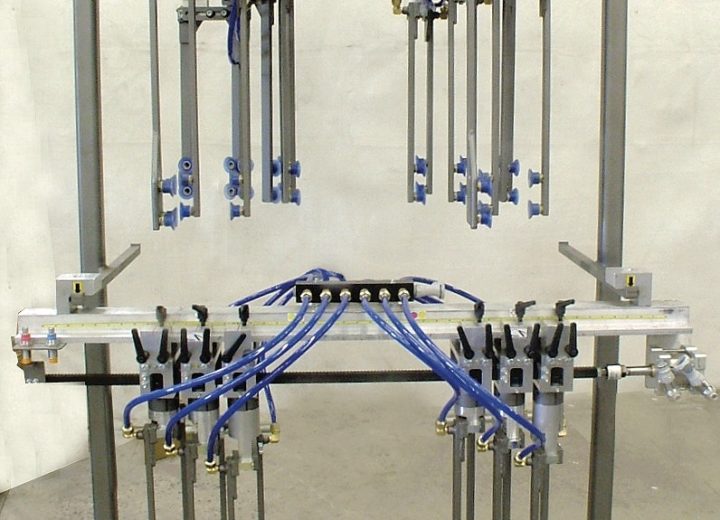

With systems designed specifically for plastic containers, we can accommodate an enormous range of possible container shapes and sizes. Whether you need a glass or plastic container packaging machine (or one of each!), Wayne has you covered.

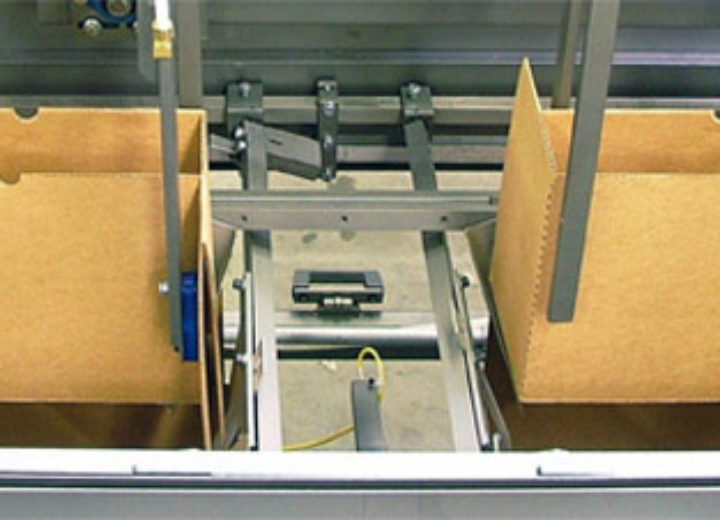

Chemical products have specific configurations for boxing and shipping, but all potentially hazardous materials require secure, sturdy packaging for distribution. Volatile or corrosive chemicals in particular require sufficiently rugged cases and packaging for safe and successful shipping. For products subject to additional regulations and requirements, Wayne can help you build an appropriate end-of-line packaging solution for your products.

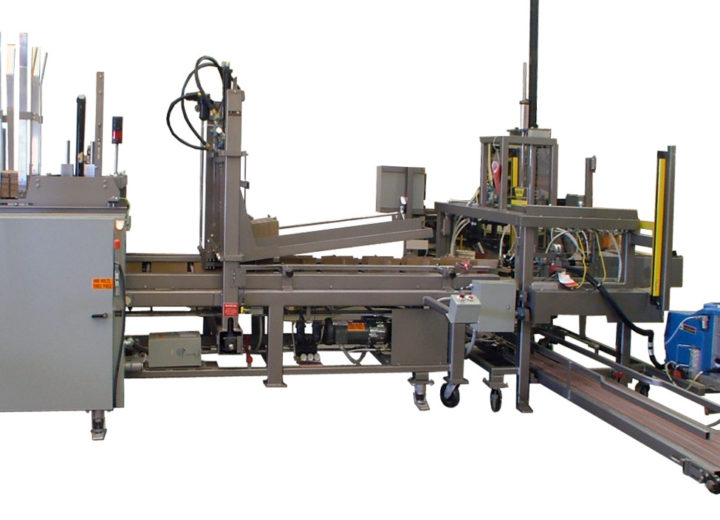

The food industry includes a staggering range of products, and food packaging systems need to rise to the occasion. From glass bottles to paper cartons to plastic pouches—packaging a wide variety of products requires fast, efficient, and flexible machines. Wayne has the right solutions you need to get your products safely boxed up and out the door.